[Ref : PAS10002]

The pasteurisation allows to remove all the micro-organisms that contaminate the human breast milk preserving at the same time a maximum of nutrients and immunological elements.

Innovation and performance

Our water pasteuriser is currently the only process that allows reaching 62.5°C very quickly and cool milk up to 4°C homogenising it at the same time during the cycle. Our Engineering Department, in connection with several milk banks, managed to combine efficiency and comfort of use.

Download the brochure Need more information? A quote?- Patented homogenisation system

- Water agitation by a propeller that allows the homogeneity of the bath to +/-0.5°C.

- Bottles agitation to ensure the milk homogenisation (only a performance qualification, allows to check the homogeneity of the sink).

- Patented cooling and water treatment cell

- Cold water reservoir for rapid cooling of bottles at 4°C.

- Bathwater filtration to 0.2 microns to avoid any contamination.

- Cooler water sterilised by a UV filter.

- Regeneration of 70% of the cooled water.

- Reliability

- The most precise device of the market.

- Sink and frame entirely made of 304 L stainless steel.

- Hygienic and resistant top plate made with Corian®.

- French manufacturing and quality.

- Ease of use, control via Programmable Logic Controller

- Multilingual intuitive control by touch screen.

- Automatic levels’ adjustements depending on load.

- Water level detection.

- Wear detection of filters.

- Insertion sensor detection.

- Automatic temperature control of the cycle and cooling.

- Self-testing and validation of the cycle.

- Storage bottles at 4°C until the user stops the cycle.

- Integrated traceability system

- Traceability connected to a PC and to your internal computer network.

- Interfacing with MO Lactarium

- Automatic archiving data and numbering of cycles.

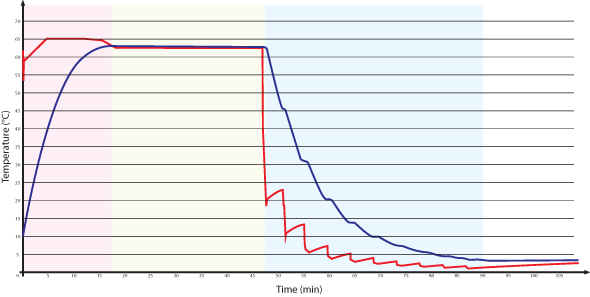

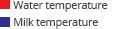

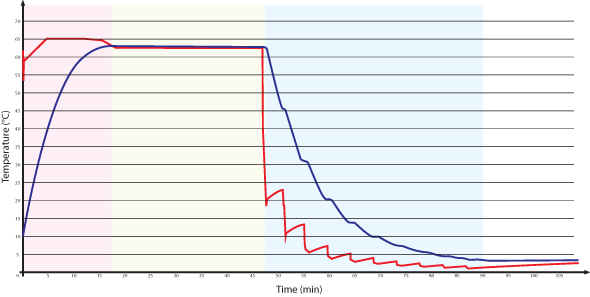

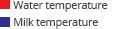

- Cycle control in real-time with time plots of temperature.

- Temperature graph of milk and water.

- Name of the operator.

- Data recording of minimum and maximum temperature.

- ata recording of holding time at temperature and cooling.

- Pasteurisation cycle

- Temperature rise: 15 and 20 minutes*.

- Holding time at temperature: 30 minutes (control of the temperature between 62.5°C and 63°C).

- Exposure time above 58°C: 36 minutes.

- Cooling at 4 ° C: 30 to 40 minutes*.

- otal cycle time: 1:30*

PAS 10002 manages a set of cycles occurring before or after the cycle of pasteurisation.

- Defrost cycle

- Defrost the milk before the pasteurisation.

- Control the milk’s temperature throughout the defrost cycle and hold it at 4°C.

- Cooling cycle

- The cooling cycle can work independently of the pasteurisation cycle.

- It allows more particularly to cool the artificial milk after conditioning.

- Decontamination cycle

- Disinfect all parts of the pasteuriser in contact with water (sink, pipes...). In option

| Denomination | Specifications |

|---|---|

| Total number of 250 ml or 130 ml feeding bottles | 3 baskets of 21 feeding bottles |

| Dimension of the standard device (length x depth in mm) | 1100 x 1170 |

| Dimension of the device with the right offset (length x depth in mm) | 2400 x 650 |

| Overall height of the device (mm) | 1120 |

| Loading height (mm) | 1000 |

| Unladen mass (kg) | 200 |

| Mass with water (kg) | 350 |

| Power (KW) | 12 |

| Power supply | 230 V three-phase + Earth 400 V three-phase + Neutral + Earth |

| Type | Denomination | Reference |

|---|---|---|

| Option | Pre-filtration of the water inlet to 1 micron | OPT7064 |

| Accessories | Basket* of 21 bottles of 250ml | PAN10010 |

| Accessories | Basket* of 21 bottles of 130ml | PAN10015 |

| Equipment | 9 litres compact water softener | ADO15000 |

| * Baskets are in high quality 304 L stainless steel, compartmentalized baskets with removable holding cover. | ||

- Patented homogenisation system

- Water agitation by a propeller that allows the homogeneity of the bath to +/-0.5°C.

- Bottles agitation to ensure the milk homogenisation (only a performance qualification, allows to check the homogeneity of the sink).

- Patented cooling and water treatment cell

- Cold water reservoir for rapid cooling of bottles at 4°C.

- Bathwater filtration to 0.2 microns to avoid any contamination.

- Cooler water sterilised by a UV filter.

- Regeneration of 70% of the cooled water.

- Reliability

- The most precise device of the market.

- Sink and frame entirely made of 304 L stainless steel.

- Hygienic and resistant top plate made with Corian®.

- French manufacturing and quality.

- Ease of use, control via Programmable Logic Controller

- Multilingual intuitive control by touch screen.

- Automatic levels’ adjustements depending on load.

- Water level detection.

- Wear detection of filters.

- Insertion sensor detection.

- Automatic temperature control of the cycle and cooling.

- Self-testing and validation of the cycle.

- Storage bottles at 4°C until the user stops the cycle.

- Integrated traceability system

- Traceability connected to a PC and to your internal computer network.

- Interfacing with MO Lactarium

- Automatic archiving data and numbering of cycles.

- Cycle control in real-time with time plots of temperature.

- Temperature graph of milk and water.

- Name of the operator.

- Data recording of minimum and maximum temperature.

- ata recording of holding time at temperature and cooling.

- Pasteurisation cycle

- Temperature rise: 15 and 20 minutes*.

- Holding time at temperature: 30 minutes (control of the temperature between 62.5°C and 63°C).

- Exposure time above 58°C: 36 minutes.

- Cooling at 4 ° C: 30 to 40 minutes*.

- otal cycle time: 1:30*

- Defrost cycle

- Defrost the milk before the pasteurisation.

- Control the milk’s temperature throughout the defrost cycle and hold it at 4°C.

- Cooling cycle

- The cooling cycle can work independently of the pasteurisation cycle.

- It allows more particularly to cool the artificial milk after conditioning.

- Decontamination cycle

- Disinfect all parts of the pasteuriser in contact with water (sink, pipes...). In option

| Denomination | Specifications |

|---|---|

| Total number of 250 ml or 130 ml feeding bottles | 3 baskets of 21 feeding bottles |

| Dimension of the standard device (length x depth in mm) | 1100 x 1170 |

| Dimension of the device with the right offset (length x depth in mm) | 2400 x 650 |

| Overall height of the device (mm) | 1120 |

| Loading height (mm) | 1000 |

| Unladen mass (kg) | 200 |

| Mass with water (kg) | 350 |

| Power (KW) | 12 |

| Power supply | 230 V three-phase + Earth400 V three-phase + Neutral + Earth |

| Type | Denomination | Reference |

|---|---|---|

| Option | Pre-filtration of the water inlet to 1 micron | OPT7064 |

| Accessories | Basket* of 21 bottles of 250ml | PAN10010 |

| Accessories | Basket* of 21 bottles of 130ml | PAN10015 |

| Equipment | 9 litres compact water softener | ADO15000 |

| * Baskets are in high quality 304 L stainless steel, compartmentalized baskets with removable holding cover. | ||

Français

Français

English

English

Español

Español